BRIEF OF THE TECHNOLOGY

The Tiny-oil Ignition Improvement can reduce more than 95% oil, and relize the ultra-low load opreation with a wide range of different coals. Its pillar product Tiny oil cold furnance ignition and ultra low load steady burning technology can ignite massive powdered coals with few oil through a specially designed burner and save oil by over 95%, which greatly lowers oil consumption used for strating and combustion supporting, and renders the plants huge benefit. Its will bring revolution in boiler ignition technology power station.

Performance and Advantage of Step by Step Energy Enlarge Design Concept

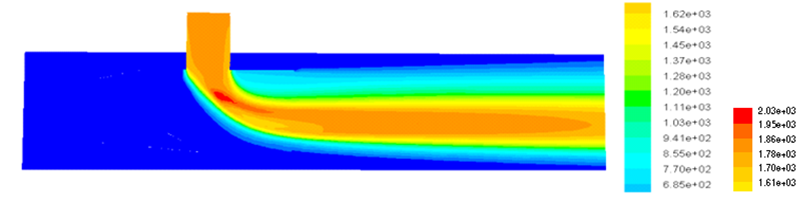

- Makes oil burning severely in a very short period of time , generates high temperature flame with intensity enlarged energy the mean temperature of the flame can reach up to 1500℃ to 2000℃.

- Easily Ignite the coal

Soft coal :400-600℃

Lean coal :600-800℃

Anthracite coal :800-1000℃

- Sufficient combustion and No-slag occurrence

|

|

| Flame of Original Burner | Flame of Tiny Oil Burner |

WIDE-SPREADING TECHNOLOGY TINY-OIL IGNITION INDUCED, AND THE RESULTS :

|

|

|

|

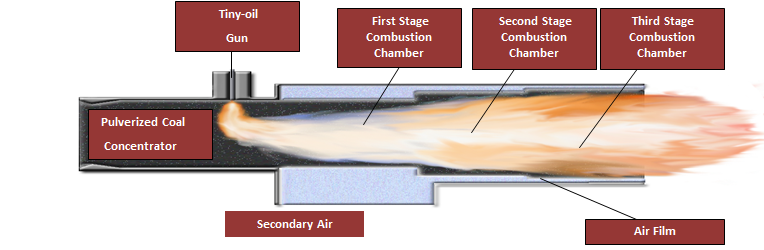

MECHANISM OF TINY OIL

Operational Theory

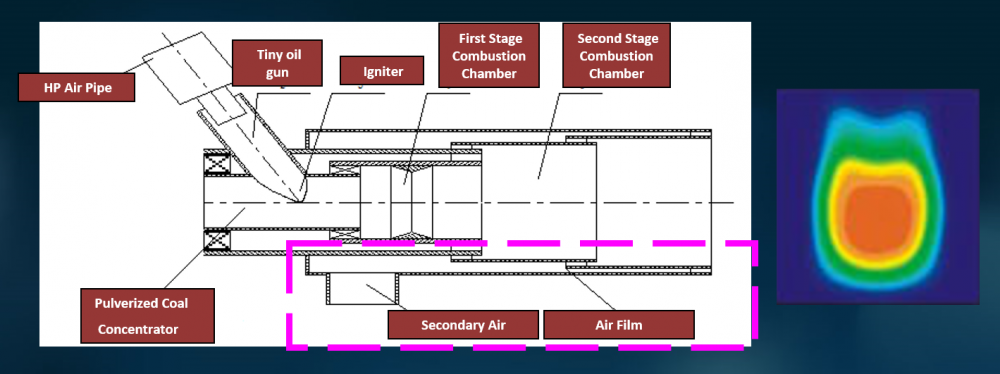

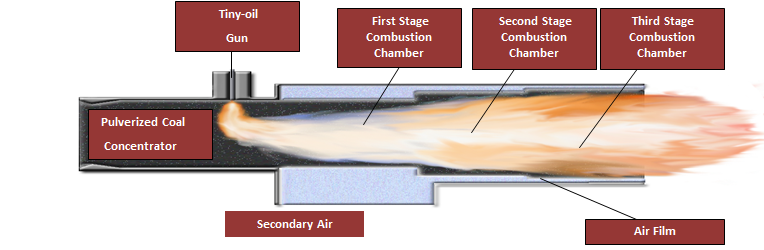

The Novel burner specially designed high-energy gasification oil gun to ignite a few of powdered coal at first stage, and then the powdered coal rationally allocated at the second-stage and third-stage will be ignited one by one by the first stage burning powdered coal, thus achieving the goal of igniting powered coal using a few oil under cold state. Around the burner, multi-stage circumlunar ring air-membrane cooling air is supplied to avoid burning-out and slag bounding and replenish oxygen neccesary for burning. It mainly consists of fuel oil system, coal-air system, powdered coal burning system, automatic control system and air preheating system.

Main Technical Indicators

A. The oil consumtion of a single oil gun is 15~40kg/h with an oil-saving rate of 95%.

B. Stable burning under 30% ultra low-load

C. Wall temperature of burner not above 600C

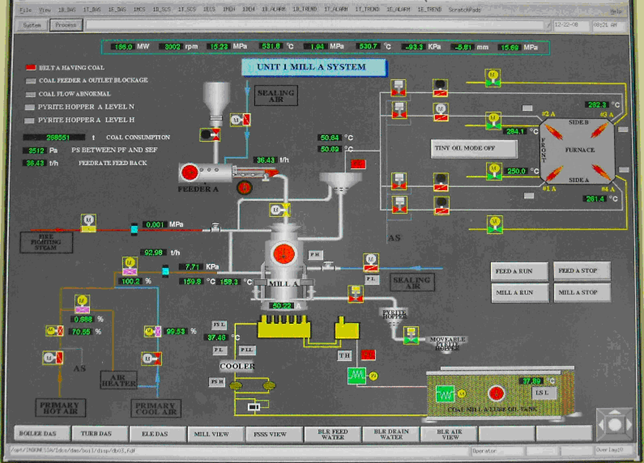

D. Automatic control of entire process

E. Satisfying the requirement on temperature rise rate and pressure increase rate of boilers.

Seven Funtional Advantages

- Igniting massive powdered cool with mini oil (15~40kg/h) and saving oil by above 95%

- Realizing cold and hot-state start and ultra-low load stable burning (below 30%) of boilers of power plan.

- Multi-stage air-membrane cooling, no slag-bonding and burn-out of burner during ignition process, low maintenance volume, high safety and reliability

- Dual-flame detection, full automatic controle, and easy, fast and safe ignition

- Simple and easy transformation, which will not impair normal running of existing equipment

- The transformed power plant boiler after ignition may be immediatelu put into electric precipitation and have good environmental protection effects

- Low investment cost and strong market competiition capacity

- Basically maintenance free

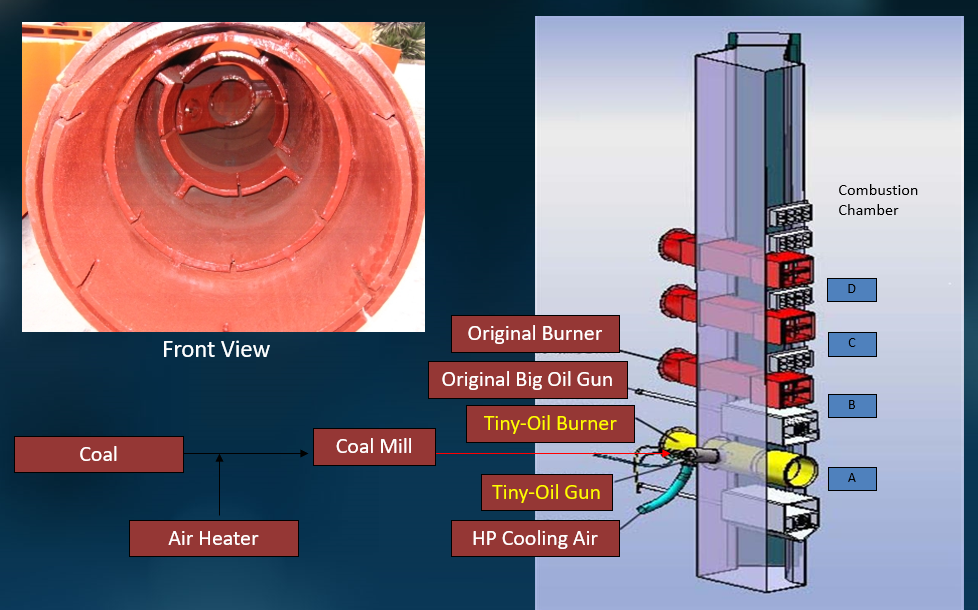

1. ENERGY ENLARGE DESIGN CONCEPT

(Direct-Firing Burner, Present In Indonesia)

|

1. Tiny-Oil Gun. |

|

|

|

2. AIR FILM SYSTEM

|

1. HP Air Pipe. |

|

3. DISTRIBUTED CONTROL SYSTEM (DCS) SYSTEM

|

1. Good security Run safely under the protection of the logic design of the oil-saving ignition .

2. Easy to use Controlled by automatic monitoring and programming operation in the whole process.

|

|